Unlock the Future of Bioprocessing: Innovative Technologies, Improved Efficiencies and Reduced Costs for your Biologics

Experience next-generation platforms and processes that empower you to deliver transformative therapies with precision, quality and scalability.

3000+ Global Attendees · 260+ Exhibitors · 200+ Scientific Posters · 9 Conference Tracks

BPI 2024 Full Agenda Now Available

Register your team by May 10 and save up to $1500 per attendee.

Learn from the brightest minds in bioprocessing

The BPI US 2024 scientific agenda includes 200+ of the industry's top scientists to present the latest updates on how to improve efficiencies across all phases of biopharmaceutical development and production.

New 2024 Agenda: Access Novel Science Across the Entire Bioprocessing Spectrum

Our BPI 2024 agenda includes 9 conference tracks covering novel science across all phases of bioprocessing for biologics, cell & gene therapies. Your registration provides access to the presentations across all 9 tracks, allowing you to create an agenda tailored specifically for your needs. Your conference pass provides on-demand access to the main conference presentation recordings for a full 12 months after the in-person event concludes.

NEW for 2024! Cell Line Development & Engineering

Advance your mAbs and beyond by enhancing your cell lines. Increase productivity, stability and yield through the latest technologies surrounding automation and data management, systems & synthetic biology and cell monitoring.

NEW for 2024! Development of Emerging CGTs

Explore the development of cutting-edge modalities, approaches, and strategies; to help you overcome roadblocks during clinical development and reach commercial stage manufacturing at an expedited pace.

Cell Culture & Upstream Processing

Maximize productivity and quality for your future pipeline utilizing automation, perfusion and media development all whilst reducing COGs.

Recovery & Purification

Leverage predictive approaches, prior knowledge, digital applications and data while applying transformative technologies to overcome bottlenecks, maximize quality and control, and enable next generation downstream processing for emerging modalities.

Analytical & Quality

Achieve a high-quality product using optimal analytical strategies, PAT and process development whilst reducing timelines.

Manufacturing Strategy & Bioprocessing 4.0

Understand strategic approaches for cost-effective and scalable commercial manufacturing of biologics. Utilize cutting edge technologies to accelerate timelines, boost efficiency and improve sustainability of processes.

Cell Therapy Manufacturing

Improve productivity, efficiency, analytical characterization and reduce cost of goods in the cell therapy manufacturing process for your products, with case study insights from Sanofi, Beam Therapeutics, and more…

Gene Therapy Manufacturing

Increase speed, consistency, and scalability to overcome manufacturing challenges during the development and commercialization of your in vivo and ‘off the shelf’ gene therapies, including learnings from Ultragenyx, Siren Biotechnology, and more…

Well Characterized Biologics & Biological Assays

Gain practical advice from case studies, FDA & regulatory leaders to accelerate your biologics & novel modalities/molecules to market.

Access Scientific Innovation at BioProcess International

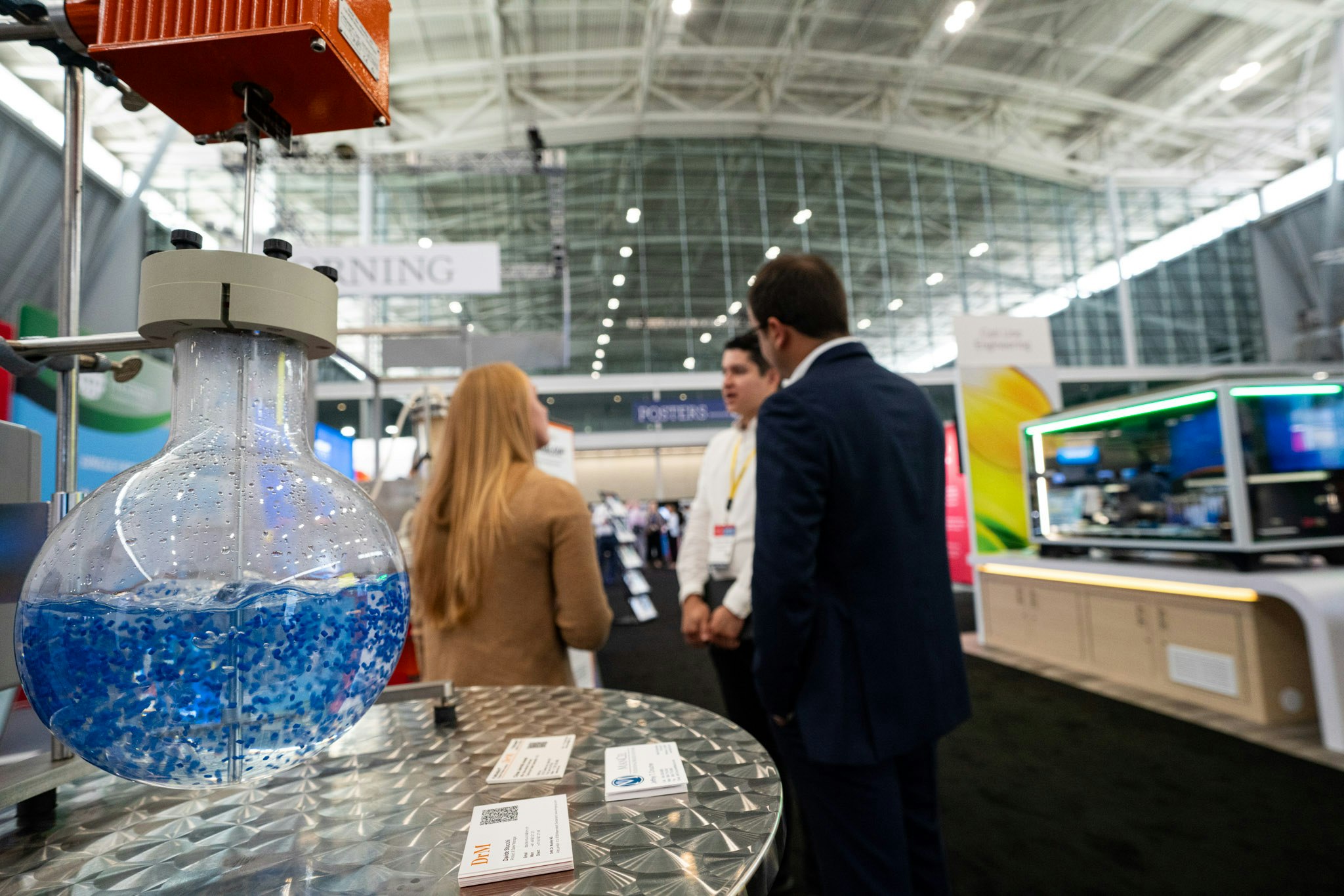

Each year, more than 3000+ bioprocessing professionals representing 40+ countries attend BioProcess International in Boston to learn about today's innovative science across the entire spectrum of biopharmaceutical development and production.

Our exhibition featured 260+ exhibitors showcasing novel technologies designed to accelerate biologics from process development through to commercial manufacturing.

Get the Latest Event Updates on BPI 2024

CONNECT WITH KEY BUYERS BY BECOMING A BPI SPONSOR/EXHIBITOR

Whether you're increasing your company profile, launching a new product or focusing on new business development opportunities, collaborate with us to identify custom solutions to help you reach your sales and marketing goals. Contact us today at Partners@informaconnectls.com to discuss.